What is a Structural Blind Rivet

A structural blind rivet retains the pin in the rivet body (sleeve) post-installation for extra tensile and shear strength. Structural blind rivets are generally available in sizes ranging from 4.8 mm (3/16’’) up to 19.1 mm (3/4'’).

The primary benefit of blind rivets is that access is only required on one side of the application, meaning you typically only need one person to install it. The single-piece design means you just push the rivet into the hole and install it. The process is very fast, clean, and safe, delivering consistent results across the board without requiring skilled personnel.

Have a look at the attached article written by Dr.-Ing. Christoph Blunk, Howmet Fastening Systems. The article What is a Structural Blind Rivet explains the terminology, installation, available materials and coatings.

Terminology

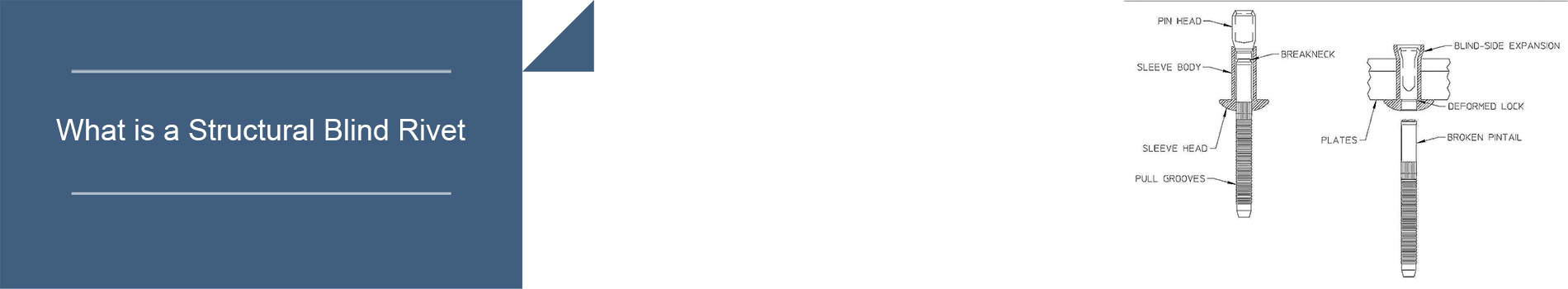

Sleeve head - The blind rivet head, or sleeve head, is on the processing side of the body, i.e., on the accessible side of the connection. Diameter and shape can vary depending on the application requirements. The most common form is the Protruding head (flat round head). Huck® fasteners are also available in Truss Head; (oversized flat heads) these are typically used to join very soft or thin materials. Countersunk heads are used to ensure there are no protrusion, enabling a smooth component surface to reduce snag risks or drag for example.

Sleeve Body - The sleeve body is the main part of the fastener behind the head that sits within the joint material (prepared hole). The sleeve body in combination with the retained pin determines the tensile performance of the rivet. The required sleeve body length is determined by the total material thickness to be joined (also known as the grip range).

Pin Head - The pin head, or mandrel head, serves to reshape the sleeve during installation and form the blind head on the inaccessible side of the joint. As it is pulled into the sleeve it forces the sleeve to deform or expand on the blind side of the combined joint materials. The head can have different geometries depending on the blind rivet type. The most common forms of structural blind rivet types (determined by the pin head function), are 1) sleeve expanding and 2) sleeve bulbing blind rivets.

Breakneck Grove - During installation the rivet pin breaks off at the predetermined breaking point after the rivet body has been formed. The rivet pin breaking force is engineered to ensure it only breaks once the sleeve is correctly formed, meaning that design and manufacturing expertise is pivotal in producing rivets that install and perform consistently.

Retained pin body - The retained pin body remains in the sleeve post installation. The contribution of the retained pin to the overall performance of the joint depends of the type of blind rivet used. Rivets where the pin breaks flush with the sleeve head, usually help to transfer external loads. Blind rivets where the pin does not break flush with the rivet head, rely on the load bearing capacity (strength) of the rivet sleeve, since it cannot be guaranteed that the pin will absorb the loads in the joint. Manufacturing blind fasteners with consistent pin break performance is heavily dependent on engineering and manufacturing skill which is often not seen in cheaper rivets.

How to choose a structural rivet?

The blind fastener that you choose depends upon the environment in which it is being used and the type and thickness of material that it is fastening together. Depending on the product, the diameter of the structural rivet can range from 4.8 mm (3/16’’) up to 19.1 mm (3/4'’). The Magna-Lok MX is a Huck® structural blind fastener that has been designed to replace M10 bolting and the Huck® BOM fastener can replace welded joints. Head types across the ranges vary, but include dome head, countersunk flanged and large flange. Star Fasteners can guide you to find a fastener that suits your application.

Specialists in the supply of Huck® fasteners and LockBolts® (pin and collar, two-piece fasteners), Star Fasteners are proud to be the UK’s largest Huck® fastener distributor. Working with a diverse range of end users and distributors from across a number of industries.

Star Fasteners are also an accredited Huck® tool service and repair centre; expert technical knowledge and a large tool hire fleet complements our service. For more information call us on +44(0)115 932 4939 or email sales@starfasteners.co.uk

Article reposted: https://www.hfsindustrial.com/news/post/what-is-a-blind-rivet?dm_i=57C9,Q4JL,U81DF,36JDS,1