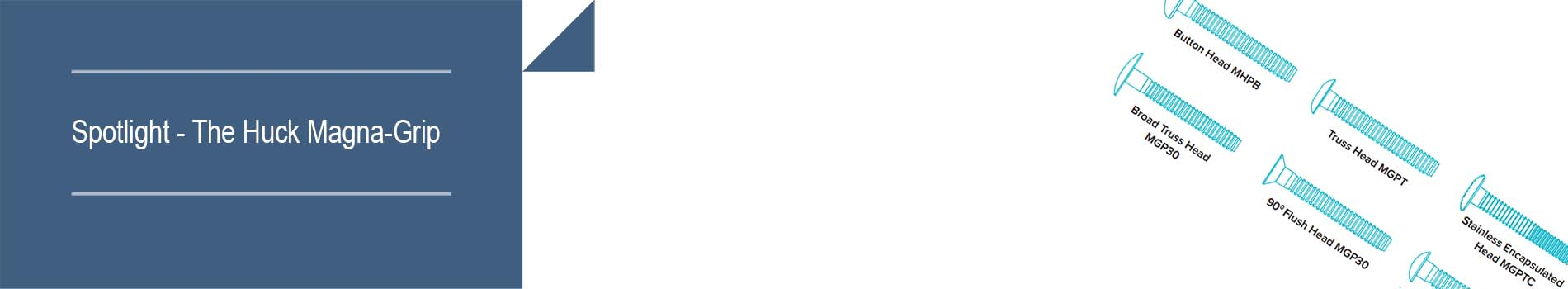

Spotlight: The Huck® Magna-Grip®

Permanent Mechanical LockBolt®

Like all Huck engineered fasteners, Magna-Grip offers a high level of vibration resistance to deal with the effects of fastening dynamic loads and is used in many harsh environments such as agricultural equipment, specialist structures, commercial vehicles and trailers, in fact wherever there is a need for a fastening solution as an alternative to welding.

In applications where a wide grip range is required and a flush pin break to the collar is beneficial, Huck Magna-Grip is the ideal fastener for the job. Magna-Grip can replace up to four traditional LockBolts. During installation the collar is swaged onto the Magna-Grip ‘pin’ and forms a permanent connection which consistently provides high, uniform installed values.

What are the benefits of using a Huck Magna-Grip fastener?

- Unmatched installation speed – fastener than standard structural bolting assemblies and no re-torque is required.

- Low overall installed cost.

- Vibration resistance - forms a permanent, vibration-proof connection that promotes increased customer satisfaction and reduced warranty claims.

- Wide grip range: reduces inventory requirements and accommodates variations in joint thickness, 14.3 - 23.9mm.

- One pin and one collar cover a wide variety of applications: reducing the risk of incorrect fastener selection.

- Eliminates need for secondary operations and hole preparation isn’t critical.

- Built-in system values yield high consistent clamp loads and gap removal.

- No special training or skills required for operators.

- Flush pin-break: no catching on clothes, skin or goods.

Available Sizes:

3/16", 1/4", 5/16", 3/8"

Materials:

Manufactured in Steel and Aluminium

The Magna-Grip is a permanent Lockbolt and is therefore an ideal fastening solution for tough engineering environments and areas where security is a requirement. One such environment is the conveyor industry. Screw conveyors, feeders and dischargers based on Archimedean screw principles are an essential part of many storage and processing systems dealing with a wide variety of products including powdered, granular and even wet materials. They are used in a diverse range of industries from grain processing, feeds and foods to oilseeds, biomass, waste and minerals. In this high vibration and abrasive environment nuts and bolts might come loose and contaminate the product and this fastening method needs ongoing maintenance and checks. The Magna-Grip is swaged and therefore offers a more secure fastening solution and eliminates the requirement of re-checking.

For over 30 years, the Huck brand has set the standard for joining technology with a range of vibration-resistant, maintenance-free fastener options. The Magna-Grip is commonly used in the commercial vehicle bodybuilding industry and is installed in wide variety of applications such as roof supports to roof rails, sider-raves to cross-bearer’s and then cross-bearers to chassis cleats. In these examples it has replaced the need for welding and nuts and bolts. For trailers, Huck fasteners offers a broad range of fasteners including HuckBolts and both structural and non-structural blind fasteners for the assembly of subframes, kick rails, various panels, roof assemblies, and floors. Each of these fasteners delivers an impressive combination of clamp, tensile strength, and zero-maintenance performance. Huck fasteners provide the industry's most advanced fastening solutions, they are 100% maintenance-free. No re-checking. No re-torquing. No re-tightening. So, a truck or trailer that is assembled using Huck fasteners represents a better value; delivers better life cycle value through, reduced warranty claims, and longer life.

Specialists in the supply of Huck Fasteners, Star Fasteners are proud to be the UK’s largest Huck fastener distributor. Working with a diverse range of end users and distributors from across a number of industries including general engineering, rail, solar, wind power automotive, marine and all of the structural construction markets. In fact, they are widely used in any industry where a quality, strong and dependable fastener is a required… application possibilities are endless!

Star Fasteners are also an accredited Huck tool service and repair centre; expert technical knowledge and a large tool hire fleet complements the service.

For more information on our products and services, potential applications, tips, ideas and product news, follow along on our social media platforms Facebook: @starfastenersuk and @starfasteners LinkedIn, Twitter, Instagram.